RP3

A plant-based ecosystem with unlimited potential for global impact

RP3 (Rapid Protein Production Platform) is a biofoundry network powered by the integration of our plant-based protein manufacturing platform, innovative technologies, and strategic global partnerships.

Our differentiated plant-based platform offers a scalable, sustainable, and cost-effective alternative to traditional methods of biologic manufacturing. By leveraging the cellular machinery of plants, RP3 has the potential to produce safe, high-quality good manufacturing practice (GMP) proteins for use in life-saving therapeutics and diverse bioactive compounds.

Smart plant growth

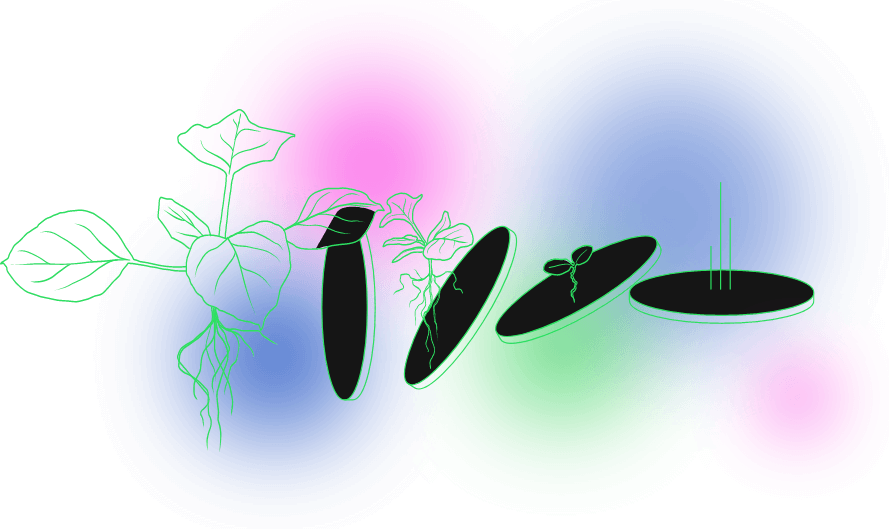

The potent capabilities of our platform start at the roots—but not all plants are alike. That’s why we utilize a proprietary seed, designed to maximize plant-based protein production and ensure safety and efficacy for use in people. Our base strain is the Nicotiana benthamiana plant, engineered to reduce immunogenicity and enable optimal protein growth.

We leverage next-generation vertical farming technologies to enhance the natural scalability of plants. Our plants are grown in indoor, automated, and contamination-free vertical towers, offering a sustainable and scalable alternative to traditional plant manufacturing. The temperature-controlled towers allow for accelerated plant growth while minimizing space and water usage.

Each step of our plant-growth process is fine-tuned to yield robust plants for maximum protein production.

We partner with agtech and biotech experts to advance plant-based manufacturing on a global scale. See how the RP3 ecosystem is optimized through partnerships with ZERO Farms and ZabBio.

Sequence to solution in 8 weeks

RP3 leverages a simple and scalable process that has the potential to revolutionize the production of antibodies, vaccines, and bioactive compounds. Equipped to handle the ever-changing demands of public health, we develop clinic-ready candidates on an accelerated timeline while optimizing safety and efficacy.

Vector building

While our plants grow, we develop a vector that contains the gene sequence for our target protein of interest. The vector is loaded into agrobacterium (a plant pathogen that can inject DNA into a plant cell) and is ready for infiltration.

Smart plant growth

Our proprietary seeds are planted in controlled indoor towers. They grow for 5 weeks before we introduce the agrobacterium solution.

Infiltration

Our plants are submerged into the agrobacterium solution under vacuum pressure. The target protein of interest is expressed in the plant within a few days of incubation.

EXTRACTION

Our plants are harvested and blended with an extraction solution.

Protein release

We perform a series of purification and filtration processes to yield a high-quality, protein-packed solution with optimal stability. The plant-made protein is then ready to be transformed into its final product.

The world moves fast—so do we

Our integrated manufacturing process is built to meet the demands of emerging public health threats and evolving consumer markets. Our therapeutic programs can be changed at the swap of a sequence, further enabling production speed and responsiveness to changing global needs.